▲

▼

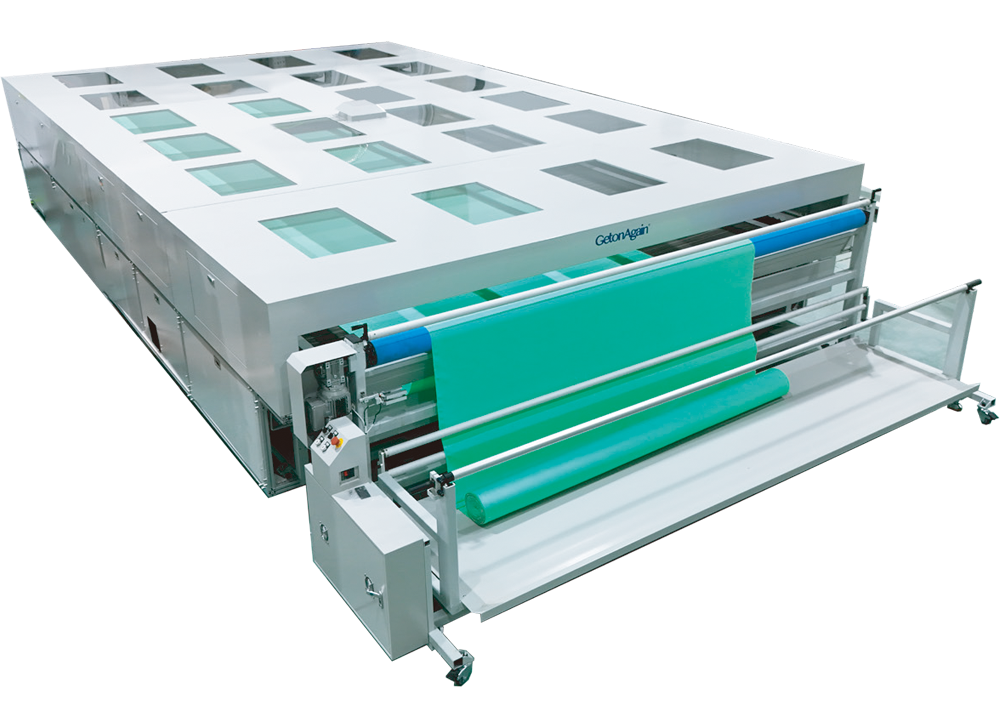

Fully Automatic Large-format Laser Cutting Machine (with Inkjet Device)

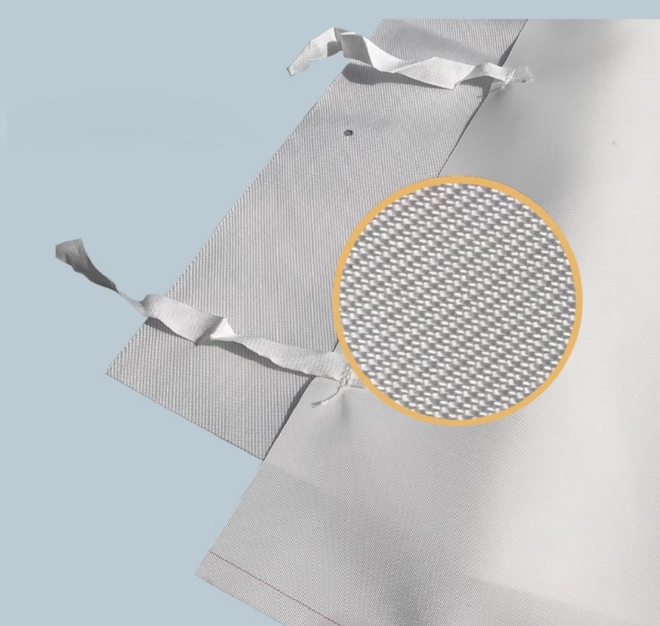

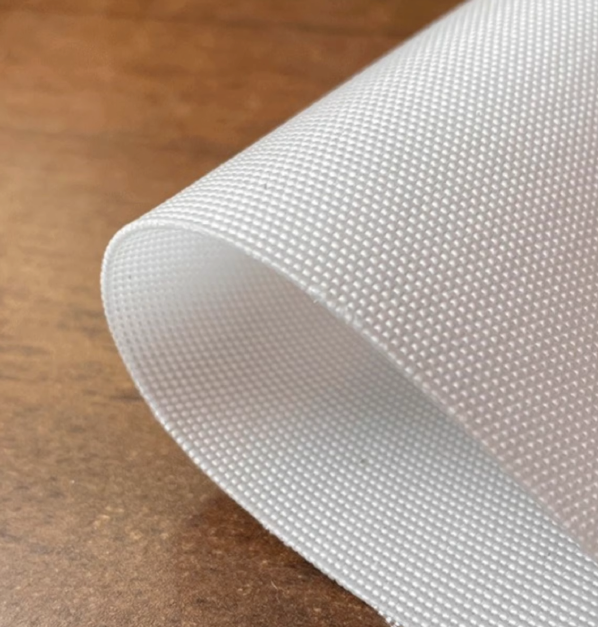

Suitable for flexible non-metallic filter fabrics, fiberglass, non-woven fabrics, foam, sponge, and other industrial materials.

.png)

Please wait a moment. The video is loading...

Equipment Advantages

- Large-format automatic feeding system: Supports the cutting and processing of whole rolls of fabric.

- Constant Optical Path Design: Ensures consistent laser output across all positions during large format cutting, resulting in uniform processing quality.

- Multi-language Support: Equipped with USB and network ports, which can be replaced based on actual needs.

- 304 Stainless Steel Conveyor Belt: Standard configuration for durability and reliability.

- Power-off engraving resume. Laser attenuation path compensation. Work time preview, with dynamic display of processing paths and coordinate points.

- Seamless Software Integration: Compatible with AutoCAD, CorelDraw, and garment CAD software, enabling direct output of original engraving designs.

- High-performance Drive System: Gantry-style dual servo motor drive system with high torque and high inertia output, significantly improving production efficiency.

- Inkjet and Cutting Functions: Integrated for enhanced versatility.

- Gear and Rack Transmission: Provides high precision and fast speed.

- Split Machine Body Design: Facilitates easy transportation.

Equipment Models

| Model | Machine Installation Size (L×W×H) |

|---|---|

| GOA,LC-NM-L-1-5000×3500-BSL-MC300-IN-3P380V | 6700mm×4200mm×1800mm |

×

Related Products

←

Small-format Camera Positioning Laser Engraver Cutting Machine

Is suitable for high-precision cutting and processing of embroidery patterns, woven label logos, and printed patterns, meeting the needs of various materials and complex designs.

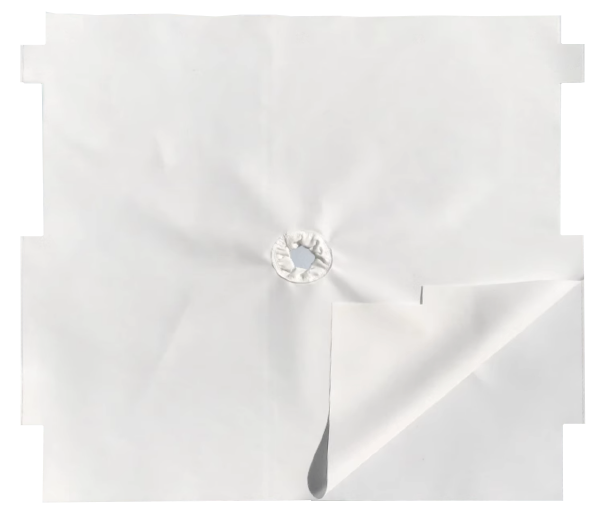

Automatic Laser Pocket Opening Machine

Front and back pockets for men's and women's clothing, suits, inner and outer pockets of jackets, dress pants, hoodies, sun protection clothing, school uniforms, sportswear, cotton-padded jackets, down jackets, workwear, jackets, uniforms, trench coats, cashmere coats, and plackets for polo shirts.

→