▲

▼

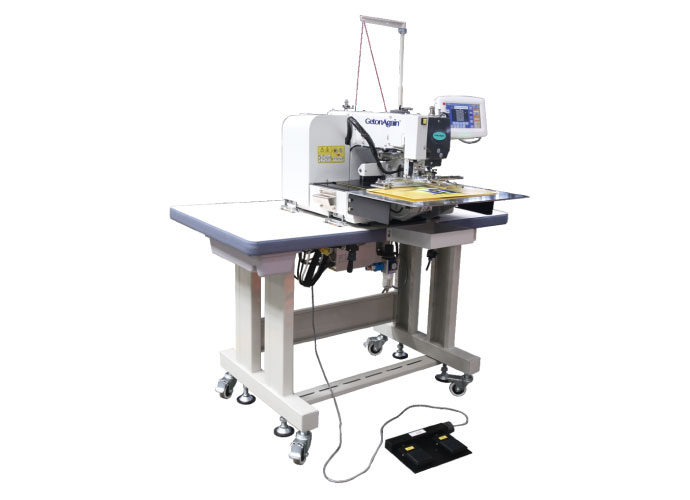

Automatic Snap Button Attaching Machine

Suitable for snap buttons in industries such as apparel, leather goods, footwear & caps, and luggage.

.png)

Please wait a moment. The video is loading...

Equipment Advantages

- Features a full touchscreen human-machine interaction interface with automatic feeding, integrated punching and fastening functions. Simple operation, energy-efficient, highly efficient, and stable operation. The button feeding track can be adjusted to accommodate different button sizes.

- Adopts general market-available electric and pneumatic button fastening molds, eliminating the need for specialized molds and ensuring easy replacement.

×

Related Products

←

Automatic Template Sewing Machine-13085

Used for template sewing processes such as opening pockets, notches, bag covers, collar trimming, etc.

Automatic Arbitrary Rotary Single Needle Leather Sewing Machine

Suitable for automated leather pattern sewing in the fields of automotive interiors, car seat covers, car door panels, airplane seats, and leather furniture upholstery.

Computer-Aided Sewing Management

Suitable for apparel manufacturing, textile processing, and other production fields requiring sewing processes, primarily used to enhance production management efficiency, quality monitoring, and product information traceability.

Direct-Drive Single-Needle Automatic Thread Trimming Compound Feed Sewing Machine-GOA-1510B-7

Suitable for regular sewing of sofas and other upholstered furniture products.

Pattern Sewing Machine

Widely used in luggage, handbags, leather goods, furniture, safety belts, binding belts, clothing.

Automatic Template Sewing Machine-3830

Used for template sewing process requirements such as patch bags, turtle backs, and labels.

Automatic Template Sewing Machine-8045

Used for template sewing process requirements such as patch bags, turtle backs, and labels.

Enhanced Direct-Drive Single-Needle Automatic Thread Trimming Compound Feed Sewing Machine GOA-1530B-7

Suitable for regular sewing of sofas and other upholstered furniture products.

Fully Automatic Mattress Top Four-Side Sewing Machine

Suitable for automatic sewing and trimming of mattress edges, widely used in the mattress manufacturing industry.

→