▲

▼

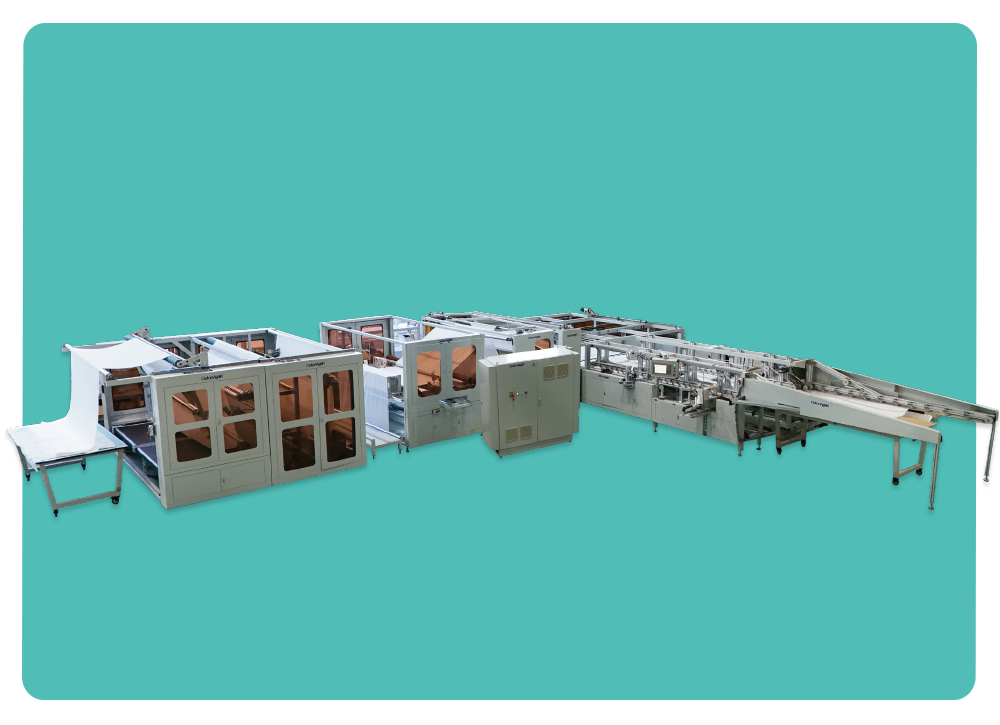

Automatic Bed Sheet Two-side Hemming Machine

Continuous double-sided hemming and cutting for bed sheets, curtains and other home-textile fabrics.

.png)

Please wait a moment. The video is loading...

Equipment Advantages

- Full servo control with GetonAgain HMI; control cabinet position customizable.

- Feeding unit handles both roll and panel fabrics, with no-material detection, auto alignment and edge trimming as standard; optional semi-automatic fabric splicer and waste collector.

- Fabric pulling unit automatically advances material to preset length.

- Longitudinal sewing head (lock-stitch, optional chain-stitch) movable for maintenance; sewing width 1500-3000 mm; hemming device 12-100 mm adjustable; thread-break auto-stop; auto-oiling.

- Rotary blade cross-cutter with optional ultrasonic edge sealing.

- Material buffer synchronizes sewing, pulling and cutting for continuous flow.

- Discharge conveyor laterally ejects stacked sheets when preset count reached.

| Model | Power (kw) | Machine Installation Size (L×W×H) |

|---|---|---|

| GOA-AS-WF-ES-2-2800X3000-2CS-NA-3P380 | 12kW | 11000mm×7000mm×2000mm |

×

Related Products

←

Automatic Bed Sheet Production Line

A fully automated bed sheet production line composed of a feeding mechanism, an adjustable-width longitudinal sewing mechanism, a fixed-length transverse cutting mechanism, an automatic transverse conveying mechanism, an automatic hemming transverse seam mechanism, and a discharging mechanism.

Quilt Roll-packing Machine III

Suitable for rolling and bagging pillows, quilts and blankets.

Multi-Needle Quilting Machine + 4-Side Tape Binding Machine Production Line

Suitable for processing quilt cores, cushions and other products with corner tape binding process.

Automatic Automatic Down Weighing and Filling Machine for Duvetsand Filling Machine for Duvets

This fully automatic down weighing and filling machine is mainly used for duvet production, suitable for various down contents (60%-95%), 3D-7D flexible fibers, and ball fibers.

Fully Automatic Mattress Top Four-Side Sewing Machine

Suitable for automatic sewing and trimming of mattress edges, widely used in the mattress manufacturing industry.

Quilt Edge Binding Machine

Designed for edge binding processes of quilts such as cotton quilts, summerquilts, spring and autumn quilts, and other bedding items.

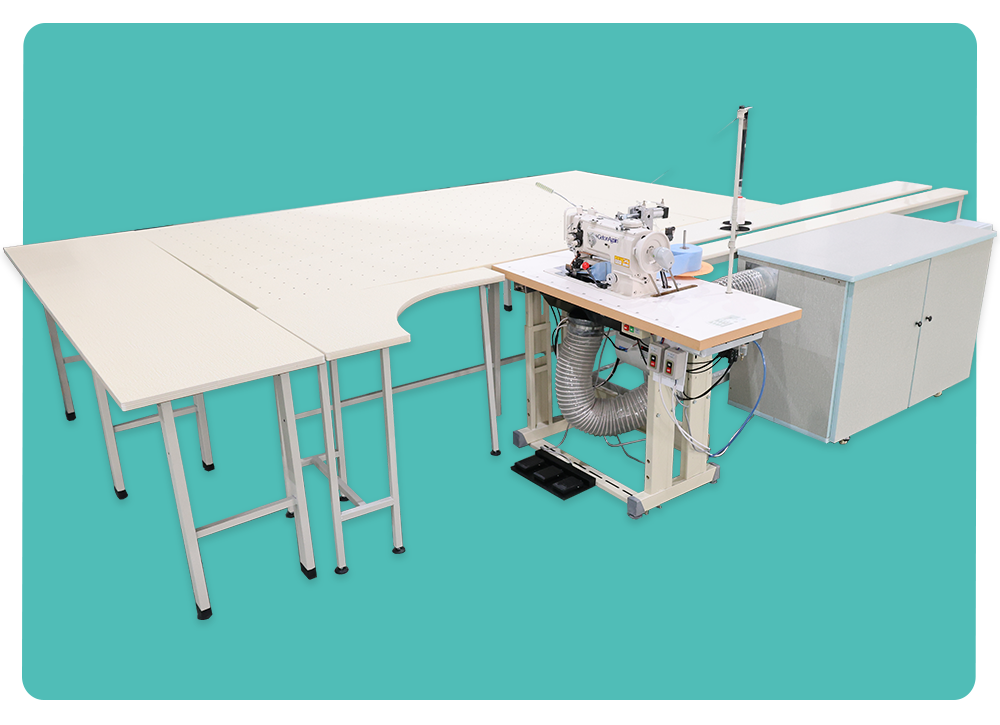

Quilts Mattress Binding with Pulling Sewing Workstation

Suitable for binding lockstitch process for quilts, mattress and cushion which are made from solid foam, latex, cotton, chemical fiber and other materials.

→

Sales@getonagain.com

Sales@getonagain.com