▲

▼

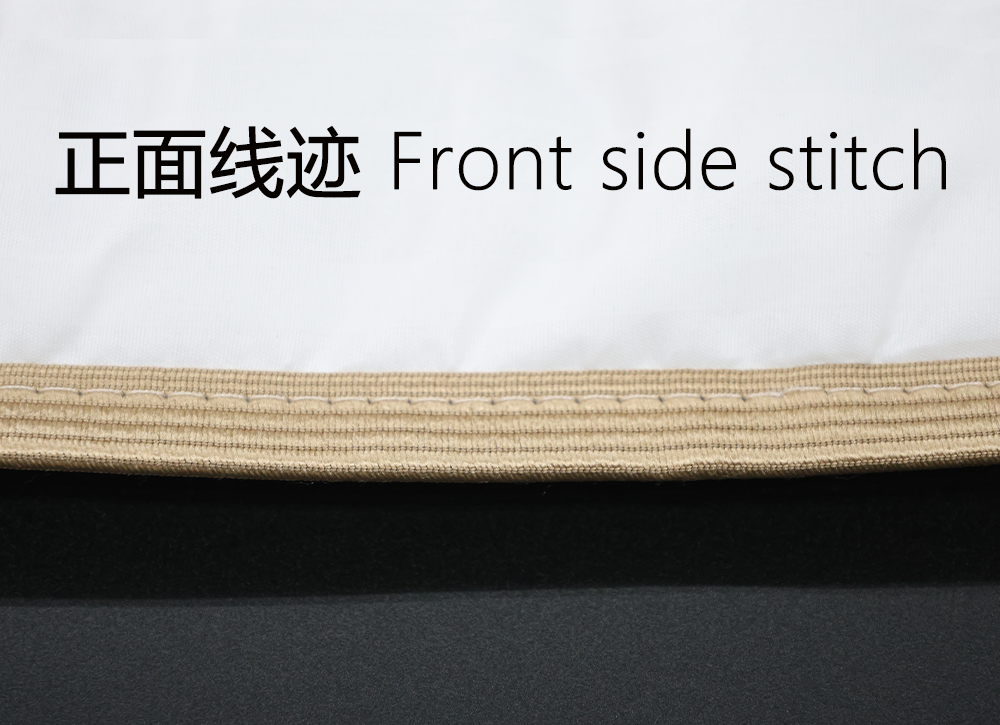

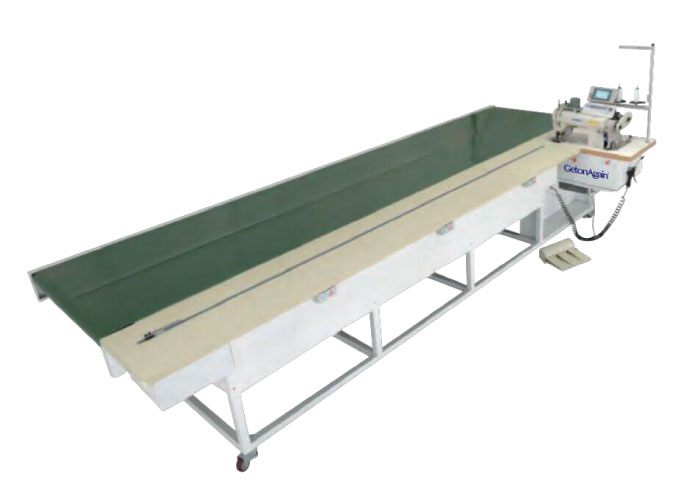

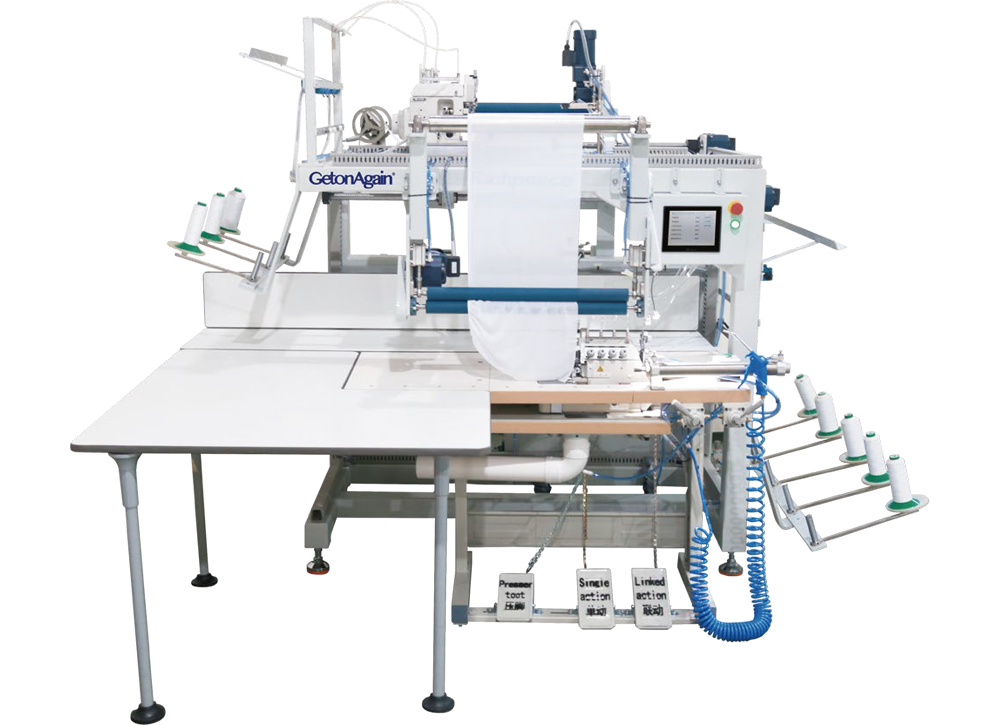

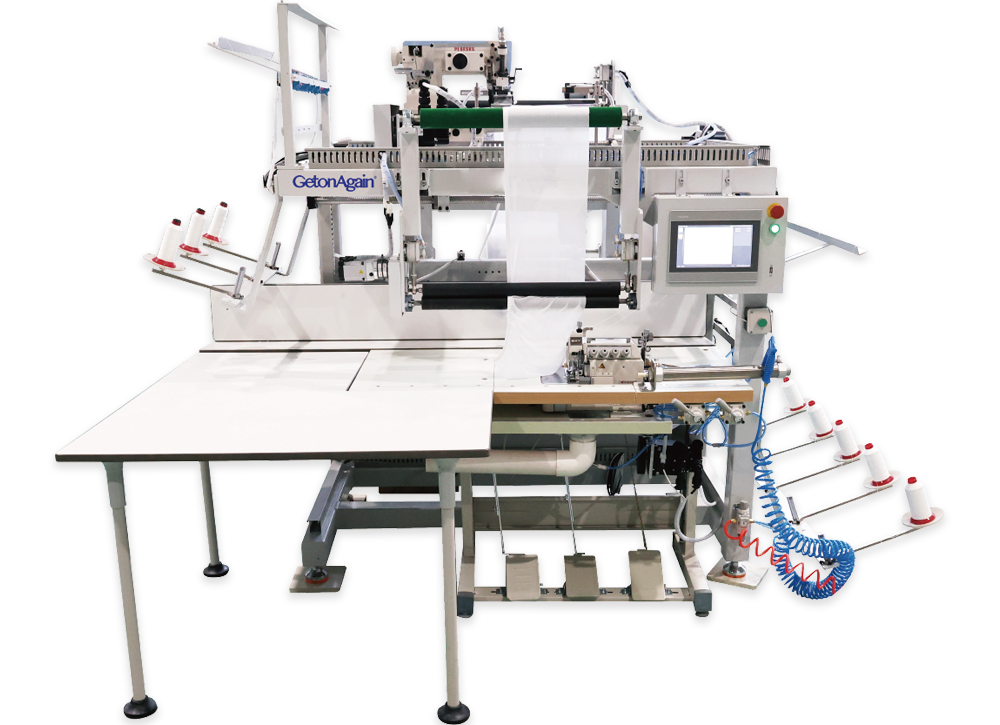

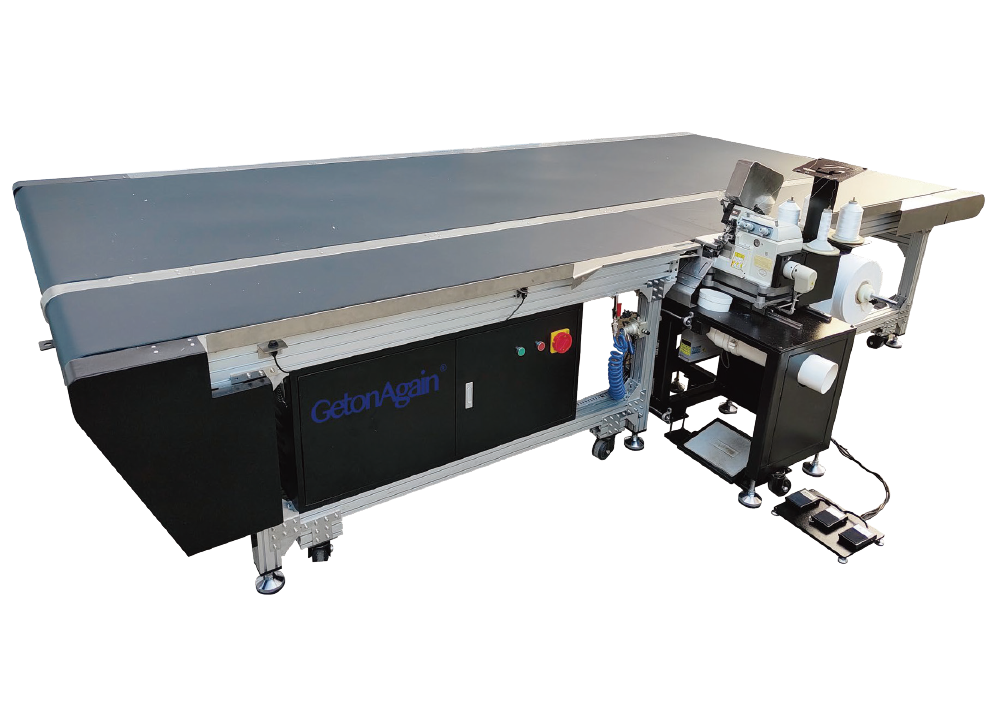

Intelligent Flat Edge Banding Machine

Specially designed for sewing mattress top panels to side border banding materials.

.png)

Please wait a moment. The video is loading...

Equipment Advantages

- Automatic Feeding System – Equipped with conveyor belt-assisted corner turning for high-speed flat edge banding.

- Standard 300UB5 chainstitch sewing head, optional with Pfaff head as customization.

- Heavy-Duty Performance – Conveyor belt synchronizes with the sewing head for seamless fabric feeding and automatic corner turning, reducing head load and extending service lifetime.

- User-Friendly Operation – Minimal training required, ensuring high efficiency and consistent output quality.

| Model | Net Weight (kg) | Power (kw) | Machine Installation Size (L×W×H) |

|---|---|---|---|

| GOA-300U-SFG | 1000kg | 2.6 kW | 4100mm×2940mm×1700 mm |

×

Related Products

←

Flat Tape Edge Machine

The Flat Tape Edge Machine is mainly used for sewing between mattress fabric and side border materials. It is also suitable for sewing other soft bedding items such as quilts, sleeping bags, and tents. Additionally, it has a new function of sewing zippers and fabrics together simultaneously.

Multifunctional Automatic Curling Sewing Machine

Curling and sewing of various single-piece fabrics such as curtains.

Automatic Edge Alignment Fabric Rolling Machine

Knit, woven, elastic fabric and other general fabric.

Automatic Mattress Protector Sewing Machine (Edge Overlock)

Suitable for processing fitted bedsheets, integrating the overlock stitching of elastic rope cord and skirt edges, as well as the overlock stitching of skirt edges and mattress protector topper sheet.

Automatic Mattress Protector Skirting Sewing Machine (Interlock+Overlock)

Edge Overlock: Interlock+Overlock: Suitable for processing fitted sheets, all-in-one to finish binding stitching of elastic rope cord and bed skirt, and the overlocking of bed skirt to mattress protector topper layer.

High Speed Mattress Flanging Machine

Suitable for flanging heavy-duty mattresses.

Intelligent Tabletop Overlock Flanging Machine

Designed for automatically conveying mattress fabrics and assisting with cornering using conveyor belts.

Intelligent Tabletop Automatic Flanging Machine

Designed for automatically conveying mattress fabrics and assisting with corner turning using a conveyor belt. A modified heavy-duty overlock sewing head based on the Japanese Pegasus/JUKI sewing machine head.

Mattress Flanging Machine

Primarily designed for sewing spring mattresses, this machine efficiently completes edge overlocking between mattress fabric and sidewall fabric.

Heavy-Duty Mattress Flanging Machine

Suitable for overlocking extra-thick mattress fabrics.

→

Sales@getonagain.com

Sales@getonagain.com